Servo driver parameter setting of PVC slipper making machine -ES510T037-R1

how to adjust the parameters of the Inovance driver for slipper making machine

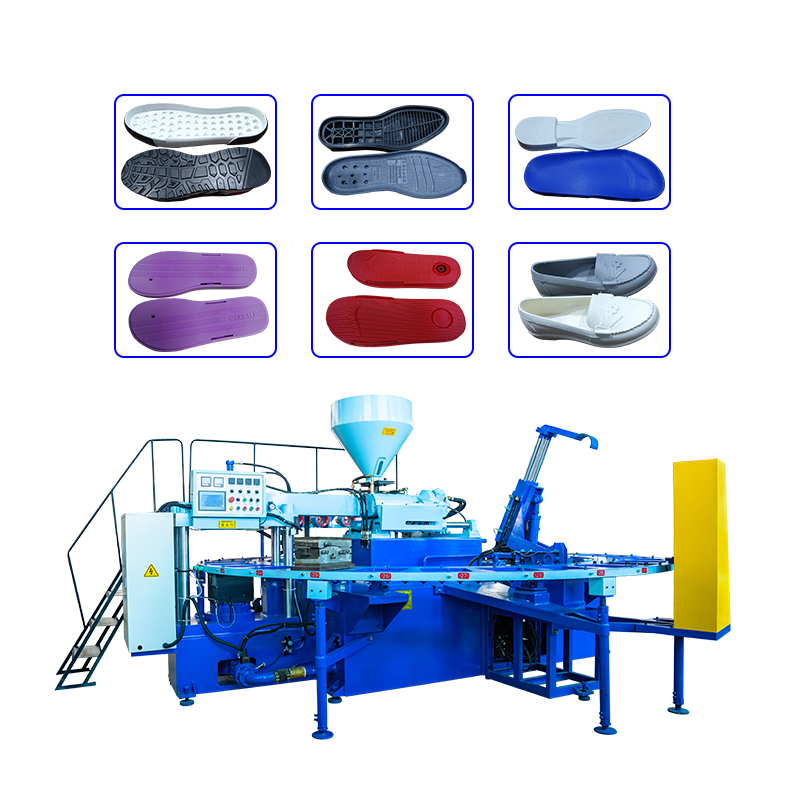

A. In the field of shoe making machines, Air blowing slipper making machine or EVA injection molding machines ,It is for order to save electric energy, the hydraulic system adopts energy-saving servo control system, which is composed of servo driver, servo motor and gear oil pump.

B.The PLC output analog DC 0-10V voltage controls the pressure in the hydraulic system. When the hydraulic pressure reaches the design value, the servo motor changes from high speed to low speed to achieve electricity energy saving. This section describes how to adjust the parameters of the servo driver of Inovance driver model ES510T037-R1 and HYSIS(PHASE) servo motor model U31008F.15.3.

C.Please following the parameters step by step to set servo drive, the servo motor can work normally.

1.FP-01,Set 1 to restore factory settings

2.F1-01,Set rated power of 16.4kw

3.F1-02,Set the rated voltage to 370v

4.F1-03, Set rated current 33.2A

5.F1-04,Set rated frequency 113.33HZ

6.F1-05,Set the rated speed to 1700PRM

7.F1-16,Set 1, static self-learning, press Enter -Run

8.F0-08,Set 5, preset frequency, press Run, confirm forward and reverse rotation

9.F0-09,Set 0 or 1, forward rotation, reverse rotation

10.A3-20,Set 1, must be set to 0 on A3-00 to set, drift self-learning, press Enter- Run

11.A3-00,Set 2, oil pressure control mode 2

12.A3-01,Set 1700 PRM

13.System pressure 140KG/CM2

The above parameters are for reference.

If you need the whole servo drive manual

please contact us.